In traditional manufacturing environments, equipment failures often occur without warning—triggering unplanned production downtime, batch-level scrap, and immediate financial loss. For decades, this reactive operating model has constrained productivity, quality, and cost efficiency.

Today, artificial intelligence is fundamentally reshaping this paradigm. AI-driven predictive maintenance is enabling manufacturers to move from reactive intervention to proactive, forward-looking operations—reducing risk while improving operational resilience.

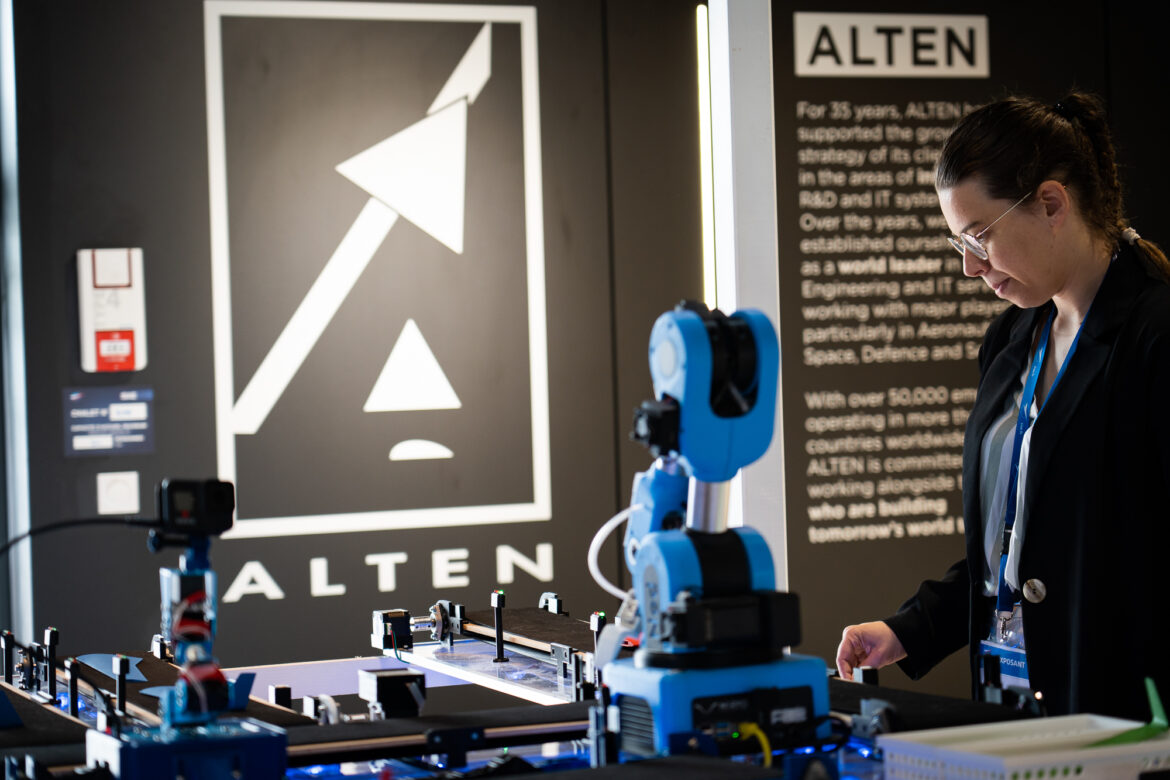

In this interview, Giuseppe Carlone, Project Director at ALTEN, shares how AI predictive maintenance is helping manufacturers anticipate issues before they escalate, delivering measurable value across multiple industries.

From Reactive Maintenance to Proactive Risk Prevention

Giuseppe notes that a longstanding challenge in manufacturing lies in the late detection of equipment degradation. In many cases, excessive wear or configuration drift is only identified at the end of the production process, by which point entire batches may already be compromised—resulting in significant waste and economic loss.

Historically, maintenance strategies have relied on fixed schedules and manual inspections. While effective to a degree, these approaches often fail to capture early-stage anomalies. Subtle signals go unnoticed, allowing latent risks to accumulate until failures become unavoidable. The result is not only reduced efficiency, but heightened operational and quality risk.

AI as an Intelligent Early-Warning System for Production Lines

In ALTEN’s implementations, AI continuously ingests and analyzes real-time sensor data, learning from historical equipment behavior and normal operating conditions. Over time, this creates an intelligent monitoring system capable of recognizing deviations that may indicate emerging failure modes.

The system can identify performance degradation or abnormal configurations in advance, predict potential failure points, and recommend targeted interventions—often before any visible impact on production occurs. This reflects a core principle of Industry 4.0 asset management: shifting from corrective maintenance to predictive prevention.

Giuseppe highlights a representative case in which the AI system issued a 60-minute advance alert indicating that a specific machine was likely to cause a decline in product quality. This early insight allowed the production team to recalibrate the equipment in time, avoiding the scrapping of an entire batch.

Those 60 minutes translated not only into avoided financial loss, but also into preserved production continuity, sustained customer confidence, and protected brand reputation. In high-performance manufacturing, time is directly linked to both quality and cost.

Data Strategy: The Foundation of Intelligent Operations

“Without reliable data, there is no reliable intelligence,” Giuseppe emphasizes. For organizations aiming to leverage AI for quality and maintenance optimization, the first priority must be advancing production line digitalization and establishing a robust data acquisition and governance strategy.

When supporting clients in deploying AI-based maintenance solutions, ALTEN consistently treats data infrastructure as the starting point. High-quality, structured data streams form the basis for effective model training, accurate predictions, and scalable system evolution—ensuring long-term return on investment.

Originally adopted in discrete manufacturing, AI predictive maintenance is now delivering value across a broad range of sectors, including:

Across these industries, one common theme emerges: data-driven foresight has become a shared foundation of smart manufacturing.

A Practical Roadmap for Deployment

For organizations considering the adoption of AI predictive maintenance, Giuseppe offers several key recommendations:

This transformation goes beyond technology alone. It represents a shift from experience-based reaction to data-driven foresight—and from firefighting issues to safeguarding operational excellence.

ALTEN’s experience demonstrates that AI does not replace human expertise; it enhances it. By enabling earlier, more accurate, and more confident decision-making, AI empowers teams to operate with greater control and predictability.

As machines gain the ability to anticipate future conditions, manufacturing enters a new era of reliable, sustainable, and intelligent operations.

Is your factory ready to see what lies ahead?

Driving Excellence in Healthcare Technology Through End-to-end Engineering

Accelerating the transition to industry 4.0

ALTEN, Bouygues Telecom Entreprises and Siemens France join forces to facilitate the development of industrial 5G

ALTEN China Assists Rockwell to Accelerate Intelligent Manufacturing